1. Self-tightening sealing cavity: The high pressure high temperature globe valve features a pressure-reinforced sealing design, with standard welded bevels at the inlet and outlet ends.

2. Hard alloy sealing system: The valve disc/seat sealing surface is made of cobalt-based tungsten-chromium-cobalt alloy, with a temperature resistance limit of 650℃ and a 300% increase in wear resistance. After 50,000 opening and closing cycles, the sealing surface integrity rate is ≥98%.

3. High-strength composite valve stem: Tempered and heat-treated matrix plus surface nitriding treatment.

4. Deep cavity corrosion-inhibiting stuffing box: Corrosion inhibitors are added to achieve zero leakage, reducing frictional torque to 60% of the standard structure.

Design Standard: ASME B16.34M

Structure Length: SME B16.10

Test and Inspection: API 598

Pressure - Temperature: ASME B16.34

Product Identification: ASME B16.34

| Nominal pressure | 150LB | 300LB | 600LB | 900LB | 1500LB | 2500LB | |

| Work pressure | 2.0 | 5.0 | 10.0 | 15.0 | 25.0 | 45.0 | |

| proper temperature(℃) | ≤570 | ≤570 | ≤570 | ≤570 | ≤570 | ≤570 | |

| Suitable media | Steam and other high temperature and high pressure value | ||||||

| material | Body, bonnet | Chromium molybdenum vanadium steel | |||||

| Disc | Chromium molybdenum vanadium steel + hardfacing alloy | ||||||

| Seat | Chromium molybdenum vanadium steel + hardfacing alloy | ||||||

| Valve stem | Chromium molybdenum vanadium steel | ||||||

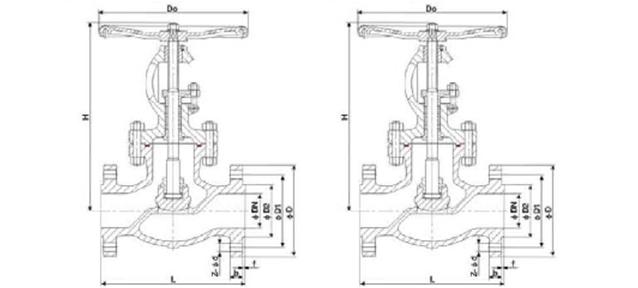

| DN | L | D | D1 | D2 | f | b | z-Φd | H | D0 |

| 150(LB) | |||||||||

| DN15 | 108 | 90 | 60.3 | 35 | 2 | 8 | 4-Φ16 | 235 | 125 |

| DN20 | 117 | 100 | 70 | 43 | 2 | 9 | 4-Φ16 | 241 | 125 |

| DN25 | 127 | 110 | 79.4 | 51 | 2 | 9.6 | 4-Φ16 | 242 | 125 |

| DN32 | 140 | 115 | 89 | 63.5 | 2 | 11.2 | 4-Φ16 | 280 | 160 |

| DN40 | 165 | 125 | 98.4 | 73 | 2 | 12.7 | 4-Φ16 | 315 | 160 |

| DN50 | 203 | 150 | 120.7 | 92 | 2 | 14.3 | 4-Φ19 | 350 | 200 |

| DN65 | 216 | 180 | 139.7 | 105 | 2 | 15.9 | 4-Φ19 | 370 | 200 |

| DN80 | 241 | 190 | 152.4 | 127 | 2 | 17.5 | 4-Φ19 | 385 | 250 |

| DN100 | 292 | 230 | 190.5 | 157.2 | 2 | 22.3 | 8-Φ19 | 454 | 250 |

| DN125 | 356 | 255 | 216 | 185.7 | 2 | 22.3 | 8-Φ22.5 | 472 | 355 |

| DN150 | 406 | 280 | 241.5 | 216 | 2 | 23.9 | 8-Φ22.5 | 541 | 355 |

| DN200 | 495 | 345 | 298.5 | 270 | 2 | 27 | 8-Φ22.5 | 590 | 450 |

| DN250 | 622 | 405 | 362 | 324 | 2 | 28.6 | 12-Φ25.5 | 780 | 450 |

| DN300 | 698 | 485 | 438 | 381 | 2 | 30.2 | 12-Φ25.5 | 870 | 500 |

| DN350 | 787 | 535 | 476.3 | 413 | 2 | 33.4 | 12-Φ28.5 | 900 | 600 |

| DN400 | 914 | 595 | 540 | 470 | 2 | 35 | 16-Φ28.5 | 1250 | 600 |

| DN450 | - | 635 | 578 | 533.4 | 2 | 38.1 | 16-Φ32 | - | 610 |

| 300(LB) | |||||||||

| DN15 | 152 | 95 | 66.7 | 35 | 2 | 12.7 | 4-Φ16 | 241 | 125 |

| DN20 | 178 | 115 | 82.6 | 43 | 2 | 14.3 | 4-Φ19 | 241 | 125 |

| DN25 | 203 | 125 | 89 | 50.8 | 2 | 15.9 | 4-Φ19 | 283 | 160 |

| DN32 | 216 | 135 | 98.5 | 63.5 | 2 | 17.5 | 4-Φ19 | 320 | 200 |

| DN40 | 229 | 155 | 114.3 | 73 | 2 | 19.1 | 4-Φ22.5 | 322 | 200 |

| DN50 | 267 | 165 | 127 | 92.1 | 2 | 20.7 | 8-Φ19 | 345 | 200 |

| DN65 | 292 | 190 | 149.2 | 104.8 | 2 | 23.9 | 8-Φ22.5 | 377 | 250 |

| DN80 | 318 | 210 | 168.3 | 127 | 2 | 27 | 8-Φ22.5 | 464 | 280 |

| DN100 | 356 | 255 | 200 | 157.2 | 2 | 30.2 | 8-Φ22.5 | 490 | 355 |

| DN125 | 400 | 280 | 235 | 185.7 | 2 | 33.4 | 8-Φ22.5 | 614 | 400 |

| DN150 | 444 | 320 | 270 | 216 | 2 | 35 | 12-Φ22.5 | 700 | 450 |

| DN200 | 559 | 380 | 330.2 | 270 | 2 | 39.7 | 12-Φ25.5 | 777 | 500 |

| DN250 | 622 | 445 | 387.4 | 323.8 | 2 | 46.1 | 16-Φ28.5 | 935 | 550 |

| DN300 | 711 | 520 | 450.8 | 381 | 2 | 49.3 | 16-Φ32 | 997 | 600 |

| DN350 | 762 | 585 | 514.4 | 412.8 | 2 | 52.4 | 20-Φ32 | 1058 | 650 |

| DN400 | 864 | 650 | 571.5 | 470 | 2 | 55.6 | 20-Φ35 | 1320 | 700 |

| 600(LB) | |||||||||

| DN15 | 165 | 95 | 66.7 | 35 | 7 | 14.3 | 4-Φ16 | 245 | 156 |

| DN20 | 190 | 115 | 82.6 | 43 | 7 | 15.9 | 4-Φ19 | 245 | 161 |

| DN25 | 216 | 125 | 89 | 50.8 | 7 | 17.5 | 4-Φ19 | 290 | 187 |

| DN32 | 229 | 135 | 98.4 | 63.5 | 7 | 20.7 | 4-Φ19 | 325 | 214 |

| DN40 | 241 | 155 | 114.3 | 73 | 7 | 22.3 | 4-Φ22.5 | 330 | 252 |

| DN50 | 292 | 165 | 127 | 92.1 | 7 | 25.4 | 8-Φ19 | 345 | 430 |

| DN65 | 330 | 190 | 149.2 | 104.8 | 7 | 28.6 | 8-Φ22.5 | 365 | 480 |

| DN80 | 356 | 210 | 168.3 | 127 | 7 | 31.8 | 8-Φ22.5 | 465 | 530 |

| DN100 | 432 | 275 | 216 | 157 | 7 | 38.1 | 8-Φ25.5 | 520 | 650 |

| DN125 | 508 | 330 | 266.7 | 185.7 | 7 | 44.5 | 8-Φ28.5 | 635 | 750 |

| DN150 | 559 | 355 | 292.1 | 216 | 7 | 47.7 | 12-Φ28.5 | 763 | 850 |

| DN200 | 660 | 420 | 349.2 | 270 | 7 | 55.6 | 12-Φ32 | 845 | 1050 |

| DN250 | 787 | 510 | 431.8 | 323.8 | 7 | 63.5 | 16-Φ35 | 930 | 1257 |

| DN300 | 838 | 560 | 489 | 381 | 7 | 66.7 | 20-Φ35 | 1010 | 1468 |

| DN350 | 889 | 605 | 527 | 412.8 | 7 | 69.9 | 20-Φ38 | 1090 | 1623 |

| DN400 | 991 | 685 | 603.2 | 470 | 7 | 76.2 | 20-Φ41 | 1140 | 1816 |

| 900(LB) | |||||||||

| DN50 | 368 | 215 | 165.1 | 92.1 | 7 | 38.1 | 8-Φ25.5 | 430 | 320 |

| DN65 | 419 | 245 | 190.5 | 104.8 | 7 | 41.3 | 8-Φ28.5 | 530 | 320 |

| DN80 | 381 | 265 | 190.5 | 127 | 7 | 38.1 | 8-Φ28.5 | 580 | 360 |

| DN100 | 457 | 290 | 235 | 157.2 | 7 | 44.5 | 8-Φ32 | 690 | 450 |

| DN125 | 559 | 350 | 279.4 | 185.7 | 7 | 50.8 | 8-Φ35 | 780 | 560 |

| DN150 | 610 | 380 | 317.5 | 216 | 7 | 55.6 | 12-Φ32 | 890 | 630 |

| DN200 | 737 | 470 | 393.7 | 270 | 7 | 63.5 | 12-Φ38 | 1240 | 720 |

| DN250 | 838 | 545 | 470 | 323.8 | 7 | 69.9 | 16-Φ38 | 1651 | 760 |

| 1500(LB) | |||||||||

| DN65 | 419 | 245 | 190.5 | 104.8 | 7 | 41.6 | 8-Φ28.5 | 530 | 400 |

| DN80 | 470 | 265 | 203.2 | 127 | 7 | 47.7 | 8-Φ32 | 590 | 450 |

| DN100 | 546 | 310 | 241.3 | 157.2 | 7 | 54 | 8-Φ35 | 710 | 500 |

| DN125 | 673 | 375 | 292.1 | 185.7 | 7 | 73.1 | 8-Φ41 | 780 | 560 |

| DN150 | 705 | 395 | 317.5 | 215.9 | 7 | 82.6 | 12-Φ38 | 904 | 630 |

| DN200 | 832 | 485 | 393.7 | 270 | 7 | 92.1 | 12-Φ45 | 1140 | 560 |

| 2500(LB) | |||||||||

| DN65 | 508 | 265 | 196.8 | 104.8 | 7 | 57.2 | 8-Φ32 | 740 | 400 |

| DN80 | 578 | 305 | 228.6 | 127 | 7 | 66.7 | 8-Φ35 | 780 | 450 |

| DN100 | 637 | 355 | 273 | 157.2 | 7 | 76.2 | 8-Φ41 | 860 | 560 |

| DN125 | 794 | 420 | 323.8 | 185.7 | 7 | 92.1 | 8-Φ48 | 930 | 630 |

| DN150 | 914 | 485 | 368.3 | 216 | 7 | 108 | 8-Φ54 | 1070 | 560 |

| DN200 | 1022 | 550 | 438.2 | 270 | 7 | 127 | 12-Φ54 | 1180 | 630 |

Address

No.1, North 1st Road, Stainless Steel New Town, Lecong Steel World West Road, Shunde District, Foshan City, Guangdong Province, China

Tel

For inquiries about gate valves, globe valves and check valves or price list, please leave your email to us and we will be in touch within 24 hours.