A swing check valve is a critical component in modern industrial piping systems, designed to prevent reverse flow and protect equipment from damage. This article provides a comprehensive overview of what a swing check valve is, how it works, its structural components, applications, advantages, material options, and how to select the right valve for your project.

A swing check valve is a type of non-return valve that allows fluid to flow in one direction while automatically preventing backflow. It operates using a hinged disc that swings open when fluid flows forward and closes when the flow stops or reverses.

Unlike manually operated valves, swing check valves function automatically, making them essential for protecting pumps, compressors, and pipelines in industrial systems.

The working principle of a swing check valve is based on flow velocity and gravity:

This simple yet effective mechanism minimizes pressure drop while ensuring reliable backflow prevention in horizontal or vertical piping installations.

| Component | Function |

|---|---|

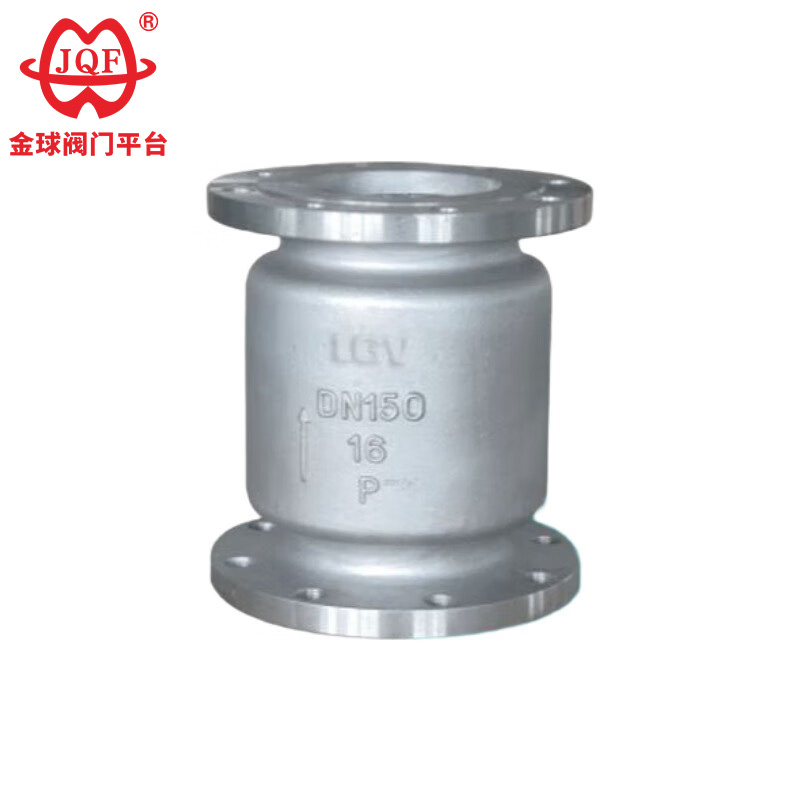

| Valve Body | Houses internal components and connects to pipeline |

| Disc | Controls flow direction by opening and closing |

| Hinge Pin | Allows disc to swing freely |

| Seat | Provides sealing surface to prevent leakage |

Manufacturers like Jinqiu offer customized swing check valve solutions based on pressure class, medium, and industry standards.

Material selection affects durability, corrosion resistance, and service life.

| Material | Typical Application |

|---|---|

| Carbon Steel | Water, oil, steam pipelines |

| Stainless Steel | Corrosive and hygienic environments |

| Cast Iron | Municipal water systems |

| Alloy Steel | High-temperature and high-pressure systems |

Swing check valves are widely used in:

Their low maintenance requirements make them ideal for large-diameter pipelines.

When selecting a swing check valve, consider:

You can explore professional guidance and product specifications through Swing Check Valve solutions.

| Type | Best Use Case |

|---|---|

| Swing Check Valve | Large flow, low pressure drop systems |

| Lift Check Valve | High-pressure, clean fluid systems |

| Wafer Check Valve | Compact installations |

Yes, but only in upward flow applications to ensure proper disc operation.

Minimal maintenance is required, mainly periodic inspection of the disc and seat.

They can handle fluids with mild impurities, but excessive solids may cause wear.

With proper material selection and installation, they can operate reliably for decades.

Understanding how a swing check valve works and where it performs best is essential for designing reliable industrial piping systems. With their simple design, low pressure loss, and proven reliability, swing check valves remain a preferred choice across industries.

If you are looking for a trusted manufacturer with engineering expertise, Jinqiu provides high-quality swing check valve solutions tailored to global standards. Feel free to contact us today to discuss your project requirements and receive professional support.